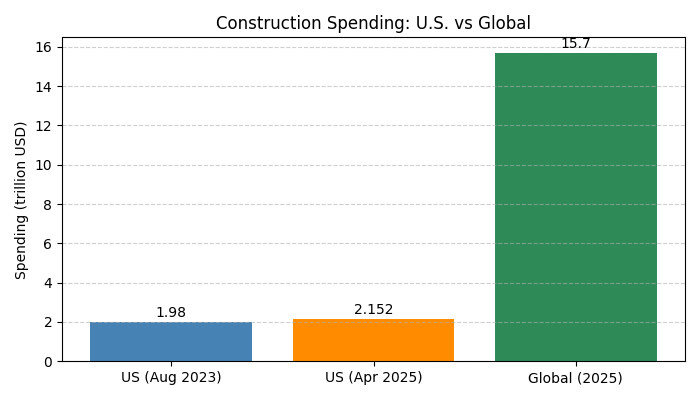

The construction industry is one of the world’s largest sectors. According to a July 2025 statistics round‑up, spending on construction in the United States reached US$2.152 trillion in April 2025, and global construction spending is expected to approach US$15.7 trillion in 2025.

Reference: https://www.autodesk.com/blogs/construction/construction-industry-statistics/

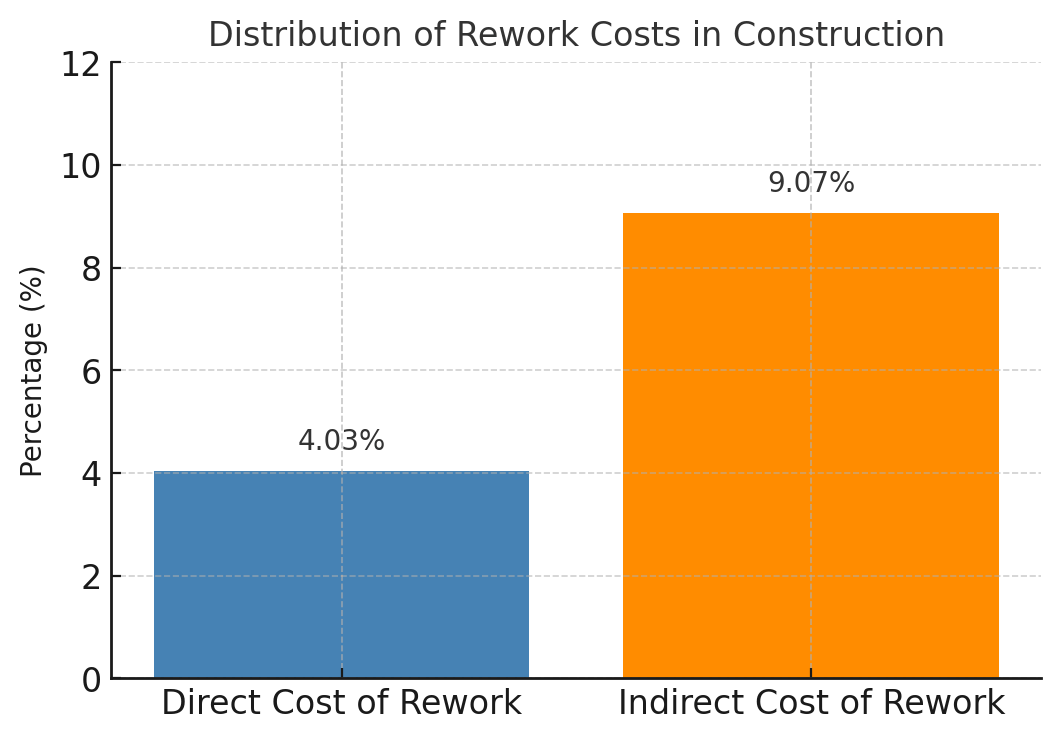

Despite this enormous scale, the sector is plagued by inefficiencies and rework. The Navigant Construction Forum estimates that the median direct cost of rework on capital projects is 4.03 % of the original contract cost, but when indirect costs (extra management time, supervision, delays) are included this range grows to 7.25–10.89 % with a median of 9.07%. In a sector that operates on slim margins, these losses are huge.

Reference: https://www.cmaanet.org/sites/default/files/2018-04/IMPACT%20OF%20REWORK%20ON%20CONSTRUCTION.pdf

Construction professionals therefore seek systematic methods for reducing defects, delays and waste. Six Sigma, a statistical process‑improvement methodology originally developed by Motorola, offers a structured approach to achieve near‑zero defects (3.4 defects per million opportunities).

When combined with Lean Construction principles like respect for people, generation of value, focus on process and flow, removal of waste and continuous improvement; it can transform project performance.

The integration of Lean and Six Sigma has been shown to improve safety, customer satisfaction, quality, schedule, productivity, profitability and risk.

Benefits of Six Sigma in Construction

Implementing Six Sigma brings tangible benefits:

- Reduced defects and rework – Data‑driven root‑cause analysis eliminates sources of variation and waste.

- Improved safety – Lean construction principles emphasize safe work methods and hazard elimination; integrated Lean Six Sigma projects have improved safety.

- Enhanced customer satisfaction – Six Sigma emphasizes voice‑of‑the‑customer and critical‑to‑quality requirements; this results in facilities that better meet owner needs.

- Higher quality construction – Standardized processes and rigorous inspections lead to fewer errors and better finishes.

- Reduced project schedule – Streamlined processes and removal of waste shorten project duration.

- Greater productivity and profitability – Continuous improvement and data‑driven decision‑making reduce labor hours and material waste, boosting margins.

- Better risk management – Monitoring key variables and establishing controls helps manage costs and avoid delays.

Quality Gurus Inc Courses

As a quality management and Six Sigma specialist with over three decades of experience, the founder of Quality Gurus Inc has created a suite of training resources to help professionals master continuous improvement. These include highly rated Udemy courses covering Six Sigma, Lean manufacturing, Lean construction, ISO 9001, statistics and ASQ certification preparation. The courses combine clear explanations with practical case studies and downloadable summary sheets, enabling students to apply DMAIC and Lean tools effectively in their projects. For construction professionals looking to integrate Six Sigma into their projects, these courses offer structured guidance on topics such as project charters, process mapping, root‑cause analysis, measurement systems analysis and control charts. In addition, Quality Gurus Inc publishes summary sheets and study guides that have helped thousands prepare for ASQ’s Black Belt, Green Belt and quality auditor exams.

To enhance your organization’s performance and reduce costly rework, consider enrolling in Quality Gurus Inc’s Six Sigma and Lean courses. Their training draws on real‑world construction and manufacturing experience, equipping participants with the knowledge and confidence to lead successful improvement projects.

Conclusion

The construction industry is vast and complex, with trillions of dollars at stake and significant inefficiencies. Six Sigma, especially when integrated with Lean principles, provides a powerful, data‑driven framework to reduce defects, minimize rework and deliver projects more safely and efficiently. Evidence shows that rework can cost as much as 9 % of contract value when indirect costs are considered.

By applying DMAIC to identify and eliminate root causes, enhancing data quality and fostering a culture of continuous improvement, construction firms can realize tangible benefits: higher quality, better safety, improved customer satisfaction and increased profitability. Quality Gurus Inc offers accessible, comprehensive training to help professionals harness these methods and make a meaningful impact on their projects.