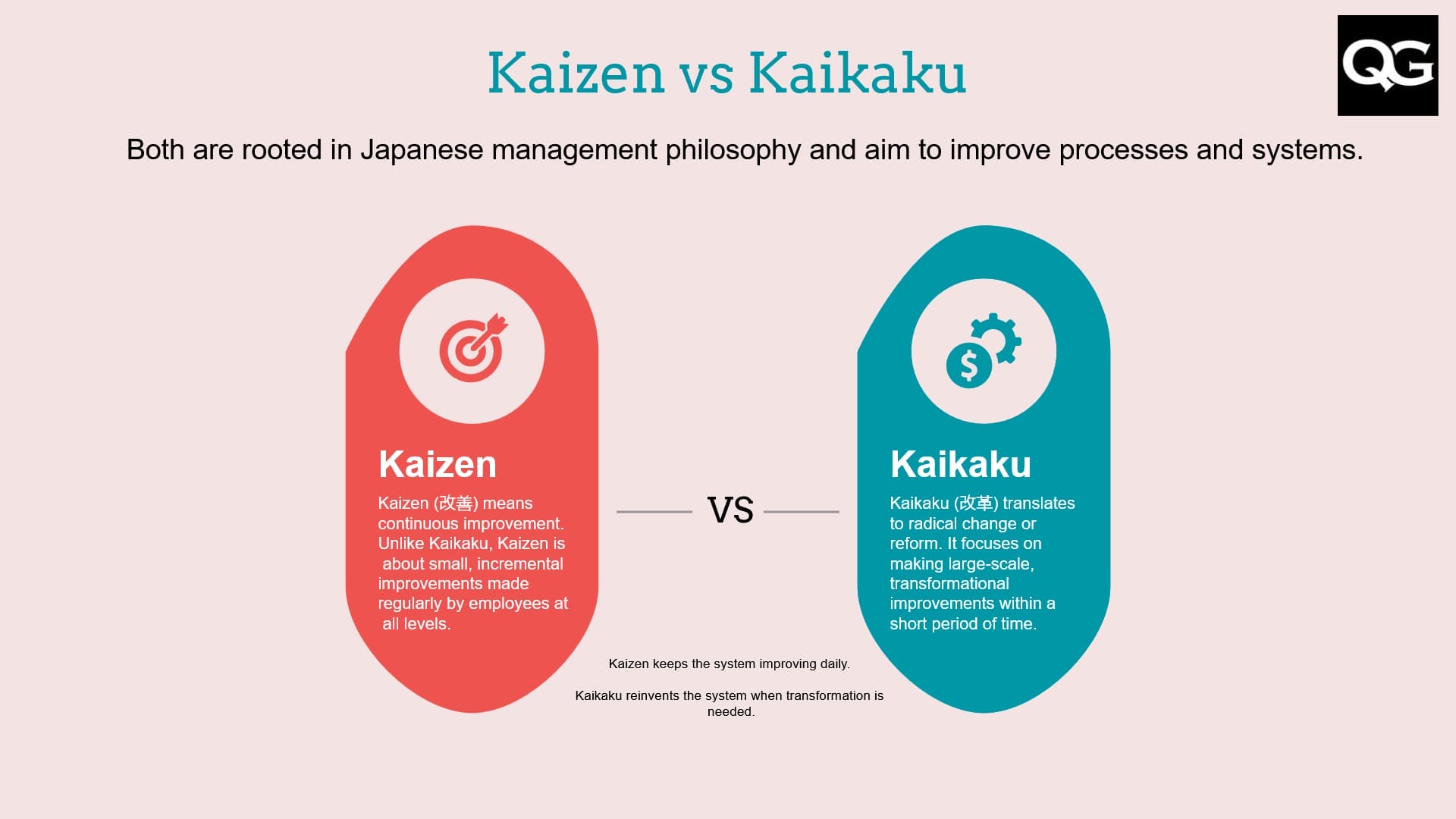

In the world of Lean and quality management, the terms Kaizen and Kaikaku are often mentioned together. Both are rooted in Japanese management philosophy and aim to improve processes and systems. However, while they share the same ultimate goal: better efficiency, productivity, and value. However their approaches are quite different.

What is Kaikaku?

Kaikaku (改革) translates to radical change or reform. It focuses on making large-scale, transformational improvements within a short period of time. Unlike gradual improvement, Kaikaku is about rethinking processes from the ground up and redesigning them to achieve significant breakthroughs.

Key Characteristics of Kaikaku:

Scope: Organization-wide or system-wide changes.

Speed: Changes are implemented rapidly, often within weeks or months.

Impact: Results in dramatic improvements in cost, lead time, quality, or customer satisfaction.

Drivers: Typically triggered by major challenges such as competitive threats, new regulations, technological shifts, or strategic initiatives.

Examples:

Replacing a manual production line with a fully automated one.

Restructuring the supply chain to introduce just-in-time delivery.

Adopting a new enterprise-wide ERP or digital platform.

Kaikaku is sometimes compared to a breakthrough project, where the organization rethinks its fundamental way of working.

What is Kaizen?

Kaizen (改善) means continuous improvement. Unlike Kaikaku, Kaizen is about small, incremental improvements made regularly by employees at all levels. It is a mindset and culture where everyone looks for ways to improve their work every day.

Key Characteristics of Kaizen:

Scope: Localized improvements in specific processes.

Speed: Small changes implemented gradually over time.

Impact: Modest improvements that accumulate to significant gains.

Drivers: Initiated by frontline employees, team leaders, and continuous improvement programs.

Examples:

Rearranging tools at a workstation for better ergonomics.

Updating a form to reduce data entry errors.

Standardizing meeting agendas to save time.

Kaizen is about engagement and ownership, empowering employees to identify problems and solve them daily.

How They Work Together

Kaizen and Kaikaku are not opposites; they are complementary.

Kaizen builds a culture of continuous improvement and incremental gains.

Kaikaku provides the leap forward when incremental changes are not enough.

Organizations that successfully combine both can adapt quickly to big shifts while also maintaining day-to-day excellence.

Conclusion

Kaizen keeps the system improving daily.

Kaikaku reinvents the system when transformation is needed.

Both are essential tools in the Lean and Six Sigma toolkit. For quality professionals, knowing when to apply Kaizen and when to apply Kaikaku is the key to driving lasting improvement and business success.

Kaikaku vs. Kaizen: A Comparison

| Aspect | Kaizen (Continuous Improvement) | Kaikaku (Radical Change) |

|---|---|---|

| Meaning | Incremental improvement | Radical reform or innovation |

| Scope | Localized, specific processes | Organization-wide, system-level |

| Speed | Gradual, ongoing | Fast, often within weeks or months |

| Impact | Small improvements that add up | Dramatic breakthroughs |

| Driven By | Frontline employees, daily efforts | Leadership or external forces |

| Examples | Standardizing a checklist, reducing waste step by step | Implementing a new production system, restructuring supply chain |