In lean and Six Sigma projects, two time-based measures often come up: Takt Time and Cycle Time. While they sound similar, they serve very different purposes and can sometimes be confused. Let’s break them down clearly.

Takt Time

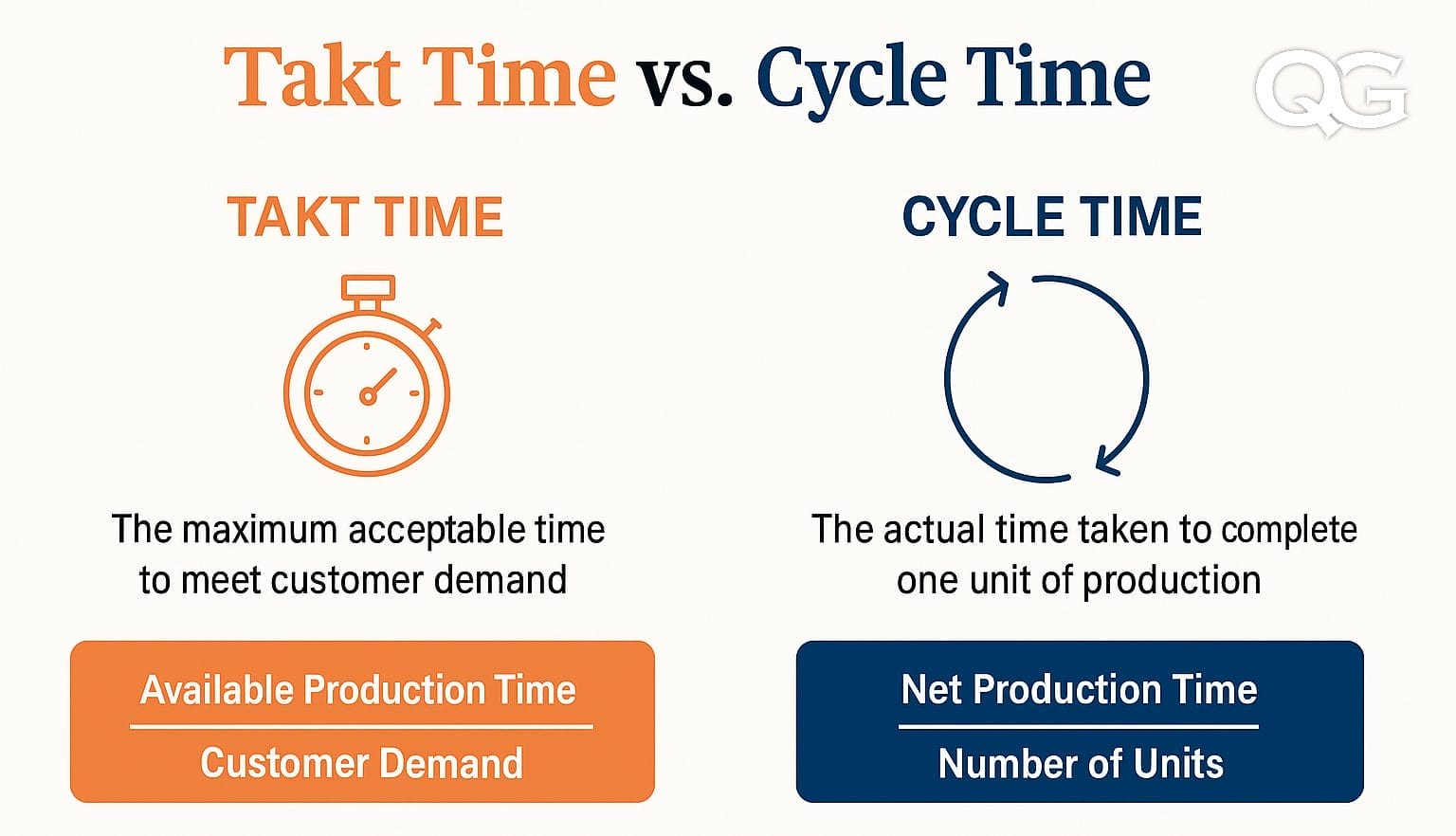

- Definition: The maximum time allowed to produce one unit to meet customer demand.

$$\text{Takt Time} = \frac{\text{Available Production Time}}{\text{Customer Demand}}$$

- Purpose: Sets the pace of production to match customer demand.

- Example: If a factory has 8 hours of available time (28,800 seconds) and customer demand is 480 units, the Takt Time is 60 seconds per unit. This means one unit should be completed every 60 seconds to satisfy demand.

Cycle Time

- Definition: The actual time it takes to complete one unit or one cycle of work.

$$\text{Cycle Time} = \frac{\text{Net Production Time}}{\text{Number of Units Produced}}$$

- Measurement: Can be the time per unit at one workstation, or the total time across the full process.

- Purpose: Reflects how fast your process is currently running.

- Example: If it actually takes 3 minutes to make one unit, your cycle time is higher than your takt time, meaning demand is not being met.

Key Difference

- Takt Time is customer-driven (pull system), ensuring production matches demand.

- Cycle Time is process-driven, measuring how fast work is actually done.

Why It Matters

- If Cycle Time ≤ Takt Time → Your process can meet demand.

- If Cycle Time > Takt Time → You risk shortages and unhappy customers.

- If Cycle Time << Takt Time → You may be overproducing, which creates waste.

Key Differences at a Glance

| Aspect | Takt Time | Cycle Time |

|---|---|---|

| Focus | Customer demand pace | Process execution pace |

| Calculated or Measured | Calculated from available time and demand | Measured directly in the process |

| Goal | Synchronize production with demand | Reduce inefficiencies and variation |

| Benchmark | External (set by customers) | Internal (set by your process) |

Conclusion

Takt Time sets the “beat” of production, like a metronome, while Cycle Time shows the actual rhythm of your process. Together, they are critical for aligning production capacity with customer demand, reducing waste, and improving efficiency.